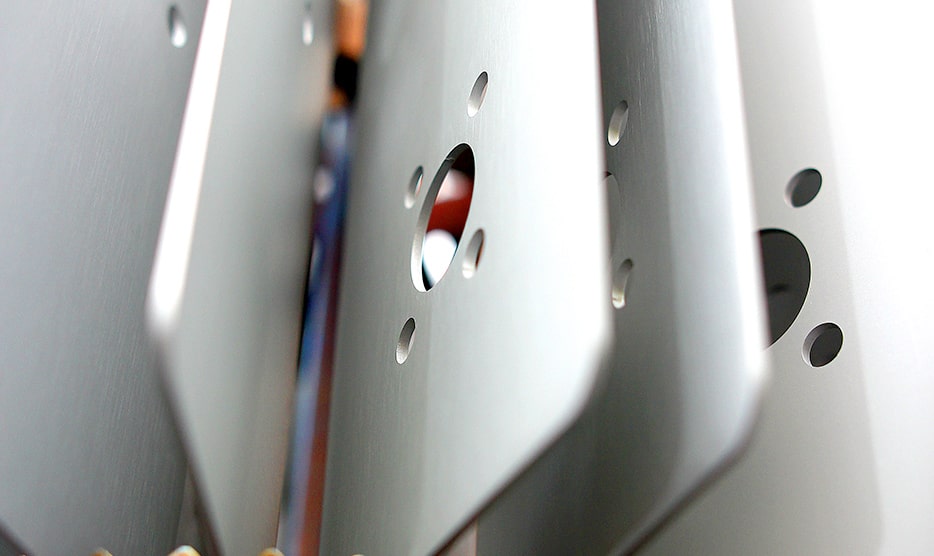

Etching

Etching produces a matt finish which will cover most extrusion lines, surface scratches and give an even coverage. If etching does not cover the extrusion lines, on your aluminium extrusions, we can also offer polishing which will blend in the surface prior to etching.

This is a very cost effective way to enhance the cosmetic look of the aluminium. This application is regarded as a good non – reflective finish for the photographic industry.

Strip Etching

If you have aluminium products that have already been anodised , this process allows you to strip the existing anodising off and to be re – anodised , either allowing you to change the colour or to a different type of finish.

Semi-Bright

This recreates the caustic etch matt finish but is complemented with a sheen using the chemical Brightening process.

Chemical Brightening

This produces a bright decorative finish to the work and is often used to create a high degree of reflectivity often required for the lighting industry.

Please note that not all aluminium alloys are ideally suited to chemical brightening. If you require any further advise on this matter please feel free to contact us on 0121 622 1850.